Solving the Global Plastic Crisis

An Interview with Suvi Haimi, CEO and Co-founder, Sulapac Ltd

Related Trend Reports

Art & Design, Business, Customization, Design, Drinking, Eco Architecture, Market, Retail, World

1. What does innovation mean to you?

The only way to solve the plastic crisis, and curb global warming, is through innovation. Most of the sustainable innovations with true potential for solving these pressing issues come from the startup sector. Hence, fostering an environment where startups can thrive should be a priority for policymakers, governments, and organizations concerned with the topic.

2. How do you and your team generate new ideas?

Creativity is one of our core values, so as a team, we are committed to finding new solutions for the benefit of our environment. As a leader, I want to nurture a culture where everyone can be themselves and also make mistakes. This allows ideas to breed freely. The mistakes made are always an opportunity for new ideas and improvement.

3. What rituals do you rely on to reset creativity?

We conduct bi-annual workshops that involve the entire company, providing us with dedicated time to strategize and reflect on our business beyond our daily responsibilities. It’s important that the physical setting is different too, so we never stay at the office, but for example, enjoy a hike in a national park instead. For me personally, nature has an important role in restoring creativity: whether it’s picking berries in the wild or walking my dog in the nearby park, being outdoors is food for your brain.

4. What is the biggest challenge you face while innovating?

Innovation is all about overcoming challenges. But if you have to name one, it would be finding the focus and balancing between resources, customer needs, and the extremely high standards that we set for ourselves.

5. How do Sulapac's materials address the global plastic crisis, particularly in terms of reducing carbon footprint and eliminating microplastic pollution?

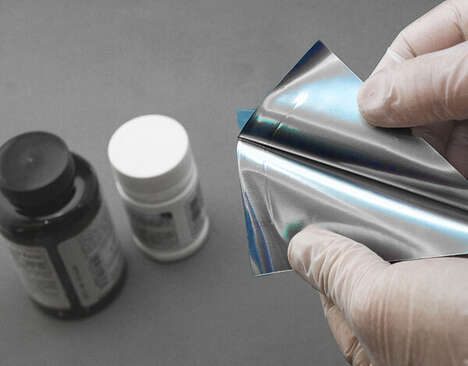

The ever-increasing plastic production leads to increased CO 2 emissions and increasing amounts of plastic pollution leaking into the environment. Sulapac materials have been designed to tackle these major global issues.

Already today plastics account for about 4% of the global greenhouse gas emissions, so there is a real urge to switch to low carbon footprint alternatives like Sulapac. By replacing conventional plastic with Sulapac, companies can reduce the cradle-to-gate carbon footprint by up to 90%. Furthermore, Sulapac materials are biobased, so they allow for the substitution of fossil-based carbon with biogenic carbon, a crucial step to keep the natural carbon cycle in balance.

Besides global warming, Sulapac is set to solve the problem of microplastic pollution. Currently, at least 14 million tons of plastic end up in the ocean every year, and all that eventually degrades into microplastics. Microplastics are all around us, in the food we eat, the air we breathe, the water we drink. Microplastics have been found even in human blood with the potential to enter our brains. So shifting to materials that do not contribute to microplastic pollution is not only an environmental imperative but also vital for human health.

The key feature of all Sulapac materials is that they leave no microplastic pollution or any toxic substances behind. Sulapac materials are safe for people and the planet even if they would leak into the environment.

6. Has another industry ever inspired innovation at Sulapac?

The entire Sulapac has been inspired by the medical biomaterials industry. Our co-founder Laura Tirkkonen-Rajasalo and myself have a background in academic research in the field of medical biomaterials where we discovered that certain material properties could have useful applications also outside the human body, namely the absence of permanent microplastics. Already back then there were concerns about microplastic accumulation in humans and the associated health risks.

Overall, I believe that solving issues like plastic pollution requires an interdisciplinary approach and collaboration across industries, which we as a company try to advance.

7. How has Sulapac been able to successfully serve customers across various industries on three continents, and what are some of the challenges faced in implementing sustainable materials on such a wide scale?

Close collaboration with our customers and partners has made it possible to bring Sulapac to new application areas and industries. Lean processes and a curious mind have also proven useful! One evident reason is also that Sulapac is easy to adopt: you can manufacture products and packaging from Sulapac with the same machinery that is used with

conventional plastic. Another success factor, in addition to the low setup cost, lies in our design principles: we create materials that are not only sustainable but also beautiful and functional, so customers don’t need to make compromises on their quality standards.

A broader success factor is our values: sustainability, creativity, and integrity. When a company chooses to collaborate with Sulapac, they get our leading sustainability expertise to help meet their sustainability targets and our genuine commitment to bring additional value to the brand.

8. With major investors like CHANEL and Sky Ocean Ventures backing Sulapac, how does the company ensure alignment between its sustainability goals and the objectives of its investors?

When selecting partners and investors, we make sure that they fully support our mission and share the same core values. When making investments in sustainable innovation, a longer perspective is required compared to “traditional” investments, and often more risk resilience too, so the starting point is overall a bit different.

We have been fortunate to find amazing allies such as Lifeline Ventures and Chanel to support our journey towards becoming the new standard in sustainable materials replacing plastic.

9. As a material innovation company founded by scientists, what research and development processes does Sulapac employ to continually improve its products and stay at the forefront of sustainable solutions?

We follow closely what happens on the academic front while collaborating with research institutions and other industry players on selected projects. However, most of the product development takes place in close interaction with our customers to ensure that the material characteristics answer to their needs.

We also make sure our innovators have a certain freedom to do their work. Although processes and protocols are useful, we are not a corporation but an innovation company set to bring about radical improvements for our customers, consumers, and the planet.

References: sulapac

Featured Articles

Dissolvable F&B

Brands are designing food and beverage packaging that dissolves in water

Aluminum Beverage

Unlikely brands are using aluminum to package their beverage products

Waste-Reduction Stay

Hotel chains collaborate with suppliers to reduce their waste

Absorbent Package

Businesses are using moisture-reducing packaging without desiccant packets